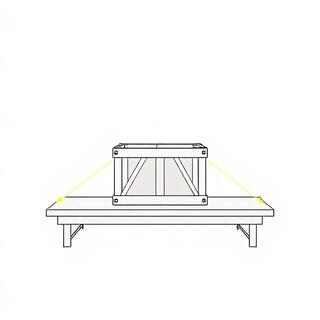

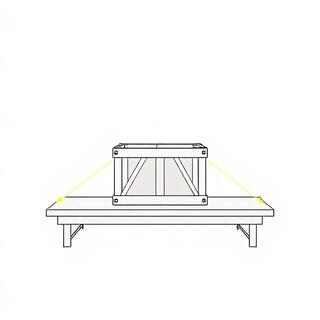

Strap geometry

Shallow strap angles (< 30°) amplify tension and risk slip. We target 45–60° with twin opposing straps to cancel lateral drift and cushion bumps.

From narrow lanes to high-rise lifts, TitanHaul orchestrates fast, careful, and compliant moves across India. Our crew plans routes like logistics pros and treats your cargo like it’s their own.

Every TitanHaul move starts with a time-boxed route plan. We map choke points, slot building access, and pre-clear permits so the crew never waits on the curb. Below is our standard flow for high-density Indian cities—from recce to unload.

We scout lane widths, turning radii, lift capacity, fire routes, and time windows. Narrow lanes often need pilot scooter escort and spotters. Findings become hard limits for the plan and fleet mix.

We align slot-based scheduling with building rules and elevator cycles. Crew is split into micro-teams—packers, loaders, riggers—so each minute is billable to movement.

We secure police/NMC permissions for temporary halts, traffic cones, and no-parking waivers, and stage PPE & pad kits for fragile surfaces. The load plan is locked here.

Heavy does not mean rough. TitanHaul trains crews to think like riggers: centre of gravity, strap angles, vector loads, and shock damping. That’s how pianos, servers, and stone slabs arrive pristine.

Shallow strap angles (< 30°) amplify tension and risk slip. We target 45–60° with twin opposing straps to cancel lateral drift and cushion bumps.

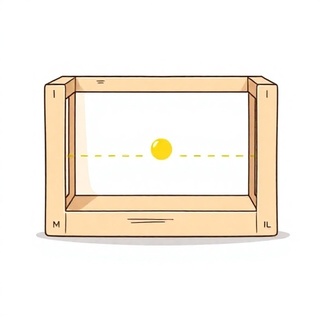

We mark CG before lift. If CG is off-axis, we redistribute pads and use a three-point base to prevent rocking. Ramps get anti-skid runners.

A 60-second lift brief reduces near-misses: callouts, hand signals, and a soft settle to absorb shock. Pads protect walls, rails, and floors.

Cities are alive—markets, rain, festivals, school rush. Our playbook adapts tactics for the three most common access scenarios. Switch tabs to see how we plan gear, crew posture, and routing.

Old-town streets can be 3.0–3.2 m wide with parked two-wheelers. We use pilot scooter to scout gaps, deploy cones, and marshal a zig-zag approach to keep traffic flowing.

Spotters handle blind corners; crew leapfrogs pads to protect walls. If clearance dips, we swap the main truck for a feeder mini-truck.

We book elevator times, pad interiors, and stage loads by weight class. Two-zone buffer (staging + loading) kills idle time.

Lift guards, corner pads, and speed caps keep tenants comfortable while our timeline stays on track.

We wrap crates in waterproof skins, lay anti-slip runners, and add drying towels to every kit. Tarps form a covered runway to the truck.

Electronics get desiccant packs; documentation rides in sealed pouches. Rain tempo adjusts so safety never slips.

One size never fits every lane. Our fleet spans agile mini-trucks for bumpy by-lanes to seven-ton haulers for express corridors, plus hydra cranes for awkward lifts. Hover items to pause the rail and read specs.

Nimble wheelbase and tight turning radius for dense colonies. Works as feeder from staging ground when the main truck can’t clear gate geometry.

Long-bed with liftgate for heavy white goods and stone slabs. Teamed with pad kits and strap triangles to keep CG centred across potholes.

For balcony lifts, roof hoists, and garden walls. Pre-rig briefing, tag lines, and exclusion zones keep bystanders safe while loads swing.

Materials are the first line of care. We test and combine pads, wraps, and edge guards so bumps turn into soft landings. Hover a card to tilt; bars show our typical spec on strength, water protection, and cushioning.

Wrap wardrobes and appliances; tape joins only on pad-to-pad, never on surfaces. Adds slip resistance and distributes point loads across corners.

Rain-tempo friendly. Heat-sealed sleeves for electronics and fabrics; seams face down-slope so runoff never wicks inside.

Foam L-guards for glass and stone. Turns sharp edges into soft geometry so straps can bite without leaving marks; perfect with opposed angles.

Smarter routes burn less diesel and stress fewer neighbours. We pre-compute time-of-day paths, plan no-idle buffers, and keep tyres & injectors in top shape. Small habits add up to measurable savings.

Engines off during pad-in/pad-out. Spotters keep the approach clear, then a coordinated push loads in one motion. Neighbours hear less, lungs breathe easier.

Our route engine avoids school bells, market peaks, and procession detours. Less braking, fewer stops, lower fuel per move.

Aligned wheels and clean injectors save fuel. Tyre pressure checks go with every morning brief; logs keep drift from creeping in.

0%

Fuel saved on off-peak routes

0%

CO₂ reduction per urban move

0%

No-idle compliance this quarter

A TitanHaul move runs on choreography—micro-teams flow through lanes with clear calls, clean handoffs, and zero clutter around lifts. The goal isn’t just speed; it’s predictable rhythm that keeps neighbours comfortable and cargo safe.

Packers kit items, tag corners, and send loads along the soft rail. The buffer captain meters flow so the lift never idles yet never clogs.

Loaders speak in short calls; one person owns strap geometry. Floor pads leapfrog to prevent scuffs, while the bed chief centres CG.

On the far end, the path is pre-walked. Spotters clear blind corners, and the receiver team resets pads so heavy items land soft every time.

Stairs are where moves go wrong—so we study them like riggers. Strap angles, hand positions, pivot arcs, and landings matter. We brief the path, anchor grips, and practice brief, lift, settle before the first step.

The lead lifts to knee height, the tail steers CG with a low pull. On each landing, we pivot on the outside foot to keep walls safe. Corners get foam guards and a runner so edges never kiss paint.

For long runs, we add ramp inserts over high risers; rubberized mats keep boots planted in rain. Calls are short and rhythmic: “lift, step, settle”.

A little prep multiplies crew efficiency. These steps shrink timelines, prevent surface damage, and help the layout at the new address feel right on day one. Open each tip for specifics.

Shift loose furniture, rugs, and planters so we have straight shots to doors. Every obstacle removed is ten seconds saved on every pass.

Use Room-Name + Weight tags (e.g., “Kitchen – Medium”). At unload we sort by room, so there’s no pile-up in the hall.

24 hours before move, empty and defrost fridges; lay towels to catch runoff. Drained machines travel safer and arrive odour-free.

Keep passports, jewellery, and sensitive papers with you. We never pack these— it’s policy for your peace of mind.

Ask the society to reserve the service lift if available. We pad interiors and run in timed bursts to reduce building traffic.

Two cones near the gate save minutes of manoeuvring. If parking is tough, we’ll stage on a side lane and feed via mini-truck.

Every move carries a logged checklist—surface protection, crew PPE, strap geometry, elevator padding, curb cones, permit stack, and final sweep-down. These checks keep neighbours comfortable and cargo pristine.

Floors get runners; corners wear foam guards; rails take soft sleeves. Doors are propped safely with pads, never bare wedges.

Service lift interiors padded, timings booked in 20–30 minute bursts. Buffer captain meters flow to avoid hall pile-ups.

Opposed straps at 45–60°; soft corners; shock-damp settle before the truck rolls. Bed chief centres CG across bumps.

Gloves, shoes, hi-viz where required. Calls are short and calm: “lift—step—settle”. Receiver team resets pads at landings.

No-idle policy at gates; cone lane keeps pedestrians safe. Pilot scooter scouts chokepoints before the turn-in.

Hallways cleared, lift cleaned, neighbours thanked. Photos and time stamps close the log for auditing.

We earn goodwill by being good guests. TitanHaul’s code of conduct lowers noise, shortens curb time, and keeps shared spaces clean. The rules are simple and firm.

Mats under dollies, soft-close pads on doors, quiet calls—no shouting. If a corridor echoes, we slow the tempo.

Cones reserve a slim lane at the gate. Spotter guides wheels and pedestrians; engines off during pad-in/pad-out.

Pads catch dust; sweep-down closes each phase. Lift interiors wiped after use; packaging never left in lobbies.

Residents always get right-of-way. If a stroller appears, we hold the pass and make the corridor generous.

Some buildings prefer night hours. We switch to low-noise gear, amber work lights, and hi-viz PPE. Decibel caps apply; neighbours sleep, crew stays visible.

Rubberized wheels, soft platforms, and slow turn-ins. Each landing gets a pad so edges never click on concrete.

Hi-viz vests and arm bands; amber work lights angled down. The truck idles off; spotters carry small beacons for corners.

Some cargo demands choreography beyond ordinary care. We combine ramp physics, shock monitoring, and soft geometry so fragile weight travels calm. Three scenarios capture our approach from setup to settle.

Low-angle aluminum ramps with anti-slip mesh; straps at opposed angles; dolly brakes tested before the first inch. Landings get foam guards and a gentle settle.

Shock loggers ride the rack; cables labeled by bay; anti-static wraps keep dust out. Lift brief covers stop word calls—anyone can halt if readings spike.

L-guards turn edges soft; A-frames lock the centre; strap triangles cancel sway. Crew rotates as a unit—no solo lifts—so weight never twists wrists.

Documentation isn’t paperwork—it’s protection. Permits, no-parking waivers, PPE logs, elevator windows, and insurance riders keep moves lawful and calm. We stamp each phase with time and crew lead.

City police permissions and society NOCs are secured in advance for curb space and cones. The pilot scooter carries copies; crew chief keeps the master folder with time stamps.

High-value items get specific riders with declared value and handling notes—CG marks, ramp angle caps, and rain protocol. Riders travel with the QA checklist.

Photos, slot logs, and PPE checks close each phase. The result is a clean trail that stands up to scrutiny and speeds dispute resolution.

From coastal humidity to dry interiors, city textures change how gear behaves. Our playbook adapts to lanes, lifts, and weather so the rhythm stays predictable. Below are core hubs and fast-response cities.

Hubs: Mumbai, Pune, Nagpur

Fast-response: Hyderabad, Bengaluru, Nashik, Indore

Rural links ride mini-trucks as feeders to the long-bed corridor, cutting dwell time at society gates. Monsoon protocol and no-idle rules apply at every site.

Whether you're planning a move, staging a space, or just have a question — drop us a note. We reply with clarity and practical next steps.